Scanning Electron Microscope with EDS and EBSD Capability

Our Scanning Electron Microscope is a high-powered microscope that is capable of analysing materials at an even more granular and microscopic level than a regular optical microscope.

Our Scanning Electron Microscope is a high-powered microscope that is capable of analysing materials at an even more granular and microscopic level than a regular optical microscope.

This impressive piece of equipment is used in materials research to aide in the development of microscopic materials such as nanotubes, nanofibers, and semiconductors while also being a useful tool for investigating materials that rely heavily on their structural integrity, like alloy metals and porous constructions.

This specific model comes with a range of features such as 3D scanning capabilities, a pressure chamber system which allows the investigation of nonconductive specimens, and Electron Backscatter Diffraction (EBSD) capabilities which makes the microscope even more powerful.

When you will use this equipment: You will most likely use the Scanning Electron Microscope when studying Materials Engineering courses and modules

Who to contact: Please contact Dr Callum Wilson at c.wilson3@napier.ac.uk for any enquiries

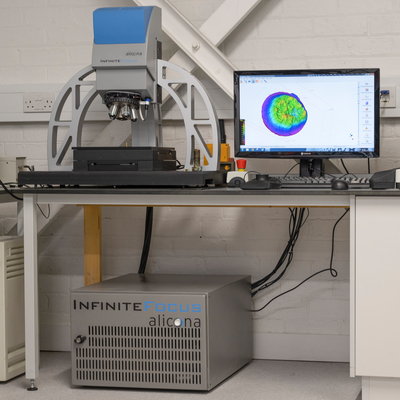

Infinite Focus Microscope – Alicona G4

Our Alicona G4 Infinite Focus Microscope can produce optical 3D images from surfaces of most materials over a large or small area. Images can then be viewed as a full 3D model for measurement and analytical purposes.

Our Alicona G4 Infinite Focus Microscope can produce optical 3D images from surfaces of most materials over a large or small area. Images can then be viewed as a full 3D model for measurement and analytical purposes.

The G4 can be used on any solid surface and is able to provide full geometrical analysis of surfaces around one square centimeter. The attached software allows for captured images to then be stored in many formats on your computer.

When you will use this equipment: You will likely use our array if microscopes when working through engineering projects and material focused modules

Who to contact: Please contact Dr Callum Wilson at c.wilson3@napier.ac.uk for any enquiries

CCT Cyclic Corrosion Test Cabinet

Our Cyclical Corrosion Test Cabinet is designed to deliver the precise environmental test conditions demanded by modern industry.

Cyclical corrosion testing is the evaluation of a variety of corrosion mechanisms caused by outdoor corrosive environments, like wind, rain, heat, humidity, aridity, and salt water.

Cyclic corrosion testing is used in all major sectors from automotive manufacture to the paint, plastics, packaging, electronics, aerospace, military and offshore industries in order to carry out accelerated corrosion and environmental testing.

This particular model provides a full range of environmental test conditions including salt spray/fog, humidity, air cycles, forced air drying, dry heat, and a wide range of temperatures.

When you will use this equipment: You will use this piece of equipment when analysing materials in your engineering course

Who to contact: Please contact Dr Callum Wilson at c.wilson3@napier.ac.uk for any enquiries

Other Equipment

Mazak CV5-500 5-Axis Machining Centre

The Mazak CV5-500 5-Axis Machining Centre is a versatile piece of equipment used for shaping metals with a high degree of accuracy and repeatability. The machine has 48 tools to choose from and a spindle that rotates up t 12000 RPM, giving it the capability to create bespoke models and large volumes of components.

The Mazak CV5-500 5-Axis Machining Centre is a versatile piece of equipment used for shaping metals with a high degree of accuracy and repeatability. The machine has 48 tools to choose from and a spindle that rotates up t 12000 RPM, giving it the capability to create bespoke models and large volumes of components.

The build in software of the machine means that students can programme the machine to create products through CAD software, like Inventor and EdgeCam for more complex models.

This is a multi-use machine that will come in handy when doing any type of metal work projects, including work on exotic and uncommon materials.

When you will use this equipment: You will likely use the Mazak CV5-500 5-Axis Machining Centre when doing metalwork modules through your engineering course

Who to contact: Please contact Paul Murray at p.murray2@napier.ac.uk for any enquiries